According to Yahoo! Finance, in 2022 Logistics automation market was valued at $49.7 billion, and is estimated to reach $147.4 billion by 2030. North America, China, Japan, India are leaders in logistic automation and inventory management innovations as they are countries of biggest port-cities that receive enormous amounts of delivery from all over the world. Not only these countries but many others use AI in Logistics to find quick solutions for operations and make the right decisions without losing to competitors.

AI replicates intelligent behavior in autonomous robots, using algorithms with minimal human intervention to leverage warehouse security, planning routes wisely, and forecasting product demand to win sales. So let’s unpack this relationship between artificial intelligence and logistics! In this article, we will discuss the use of AI in logistics, its advantages, the necessity of AI for warehouse logistics and some insights you wouldn’t wish to miss.

- What is Artificial Intelligence in Logistics?

- Robotic Systems to Modernize Warehouse Management

- AI in Logistics for Demand Forecasting

- AI Helps Organize Freight Shipping

- Machine Learning in Logistics

- AI in Robot-Delivery Services

- AI-Driven Voice Assistants

- AI Monitors Performance and Security

- Benefits of AI in Logistics

- Logistics data analysis

- Process automation

- Improved performance and security

- Accelerated and improved delivery

- Final Thoughts

What is Artificial Intelligence in Logistics?

Artificial intelligence has been known since 1956 and was firstly used in inventing board games like checkers or backgammons. Then researches in AI have come closer to Machine Learning in Logistics and Deep Learning which have much to do with neural networks. More precisely deep learning is trying to mimic the human brain – see and differentiate objects based on their attributes. So, AI in Logistics has all chances to classify images concerning one another to identify the content. Let’s say the content would be what’s placed on a shelf at the warehouse.

Deep learning as a subset of machine learning has become a breakthrough technology in image recognition and allowed logistics companies to eliminate slow-moving handwork. Two of the key branches of deep learning technology are:

- Object detection

- Instance segmentation

Deep learning led to significant improvements in the quality and speed of the supply chain. AI systems can learn from human decisions, copy data from one system to another, fill in web forms, make judgments, and interact with humans. Thus, Artificial Intelligence in Logistics are designed see things just like humans which allows substituting manual time-consuming repetitive work with automatic machines and reaching several times higher performance.

What are the phases of creating smart enterprise software?

Robotic Systems to Modernize Warehouse Management

Warehouse management faces challenges of limited space and an increasing amount of transfers at existing manual operations. Moreover, warehouse businesses can maintain efficiency with the help of robotics and AI. Imagine autonomous 4-meter robots that move along the aisles, stop at necessary places and load shelves with goods. We use AI to create robots for warehouses which help with:

- Faster pallet transporting and handling

- Reduction and optimization of aisles width

- Easier double deep packing

Such robots are AI-based and are designed to pick multi-size packages, use visual recognition to identify goods and control them via custom software. Just look at Amazon robots warehouses – they handle billions of goods yearly. And this is all due to smoothly driving robots that move autonomously without crashing into each other as if being real humans who understand where they are going and on what row of shelves they need to place packages. Computers track the performance of robots and their actions, which excludes risks of “losing” goods and uncontrollable inventory.

AI in Logistics for Demand Forecasting

How to estimate the number of products that users will want to purchase? Analyzing in-stock and out-of-stock goods, AI can predict demand, provide accurate forecasts for markdown and help with discount optimization. Trends can influence decisions on inventory and sales, so AI prediction is part of predictive analytics. It takes some marketing data and real-time data from internal sources of organizations to analyze, compare and give out some estimations.

Logistics organizations operating big data can benefit from predictive analytics in making data-driven and well-thought decisions. They will experience accurate sale estimations for the future, know risks in shipment, or discover shortages of which products can happen over a while.

Find out the advantages of enterprise management systems for logistics!

McKinsey reports that AI can reduce errors by 30% in the supply chain and decreases warehousing costs by 40%. Consequently, it leads to better sales due to predicted out-of-stock situations. Organizations that use big data tools and AI avoid storing stocks of goods that are no longer fashionable or needed and stay unsold for months. Even analyzing short periods of sales, AI systems can help companies successfully manage unexpected spikes in demand.

Recall how the youth all over the world was captivated by spinners and every young boy wanted this toy in his hand after watching a viral video. Imagine the number of increased demand. Merchants would not be able to invent something to accelerate production and delivery. Once again AI was the first to predict the popularity of spinners and prepare companies for unexpected news.

According to a report on artificial intelligence (AI) by DHL and IBM, computers already knew that the demand for fidget spinners was about to explode before the video even became viral.

Source: DHL Logistics of Things

Read more: warehouse management system functionality

AI Helps Organize Freight Shipping

Cargo or air freight shipping across oceans, let’s say from America to Europe, are not easy to organize. You have to find a transportation company at the best price, prepare proposals with custom expert agents, negotiate with sales representatives, provide route planning, avoid additional costs and plan movements with sea or air carriers in opposite directions. AI cloud-based platforms generate in seconds transport providers and display data such as price, time, and option. AI optimization helps select the most profitable journey and regulate situations such as delays or cancellations.

Learn more: custom fleet management software development

Machine Learning in Logistics

Machine learning in logistics is used for intelligent route optimization, intelligent sorting and predictive network management. The latter means machine learning models process internal data, understanding different parameters and temporal indicators like departure days, and airline performance and predicting time delays in air freight shipment. Air Freight companies always have flights planned and exact scheduling when and which planes are the first to freight. Logistics startups use AI to reduce trucking costs.

TNX company says tier software reduces trucking costs by 7-12%. The key idea of a developed product by TNX is to apply machine learning to decide on a tendering strategy. The time of making offers, to whom they are addressed, pricing and other processes are automatized.

Intelligent sorting is the greatest example of AI and ML usage in logistics. It is the effective sorting of parcels by high-speed AI robots. These systems move on the conveyor by the algorithm and have in-built cameras, and sensors to scan things nearby and receive necessary data: logos, labels, forms and sizes of parcels. The Finnish company Zenrobotics have developed AI-powered robots which can sort 4000 items per hour.

AI in Robot-Delivery Services

Daily, supply chain companies generate a high volume of data. Enabling applications to predict changes, as well as a vehicle to perceive environments, is impossible without Artificial intelligence. In fact, startups, effectuating last-mile delivery robots, have already developed battery-powered autonomous vehicles.

Discover the best functional programming language for data science!

Starship company creates small autonomous robots on six wheels to reach urban areas and deliver food to people. Amazing Nuro startup launched by former Google engineers is also worth your attention: mini electric vans with sensors carrying your food at pretty high speed. AI-powered systems are taught to predict the speed of autonomous vehicles and fuel consumption based on historical data from other vehicles. Moreover, AI systems understand weather conditions and differentiate obstacles on routes such as pets, people, cars, etc.

Inventions even know how to comply with road regulations and avoid speed limits. The demand for autonomous delivery vehicles has largely increased during the global pandemic caused by COVID-19. Robots in Logistics certainly enlarge companies’ capabilities struggling to satisfy clients with fully personalized and fast delivery.

AI-Driven Voice Assistants

Misunderstanding in daily communication between two people is estimated to be 6%. AI shows a word mistake rate of 5%. It means AI is starting to surpass humans’ intellectual capabilities, making fewer errors in ongoing processes. Text processing is the most mature capability of AI. Speech-to-text tools and speech recognition apps are used widely in logistics in automatic documentation filling and other automated processes.

Warehouse management benefits a lot from AI voice assistants allowing personnel to receive data any time they need it, communicate issues on the spot, react to challenges without handling paper documents and spending hours on finding a solution.

AI Monitors Performance and Security

Predictive risk management decreases the likelihood of occurring issues at warehouses or during transferring goods. Technology, engineering, and manufacturing leaders have to be sure of the sufficiency of processes and know in advance problems with material or equipment shortages or poor labor allocation. Predictive risk assessment can tell about traffic in cities, and explore weather conditions or any breakages at systems used by workers. So, this is one more application of AI – to control the state of equipment for production. Usually, AI robots or systems have in-built sensors that define the state of equipment. What’s more, they provide visual or audible notifications in case of problems.

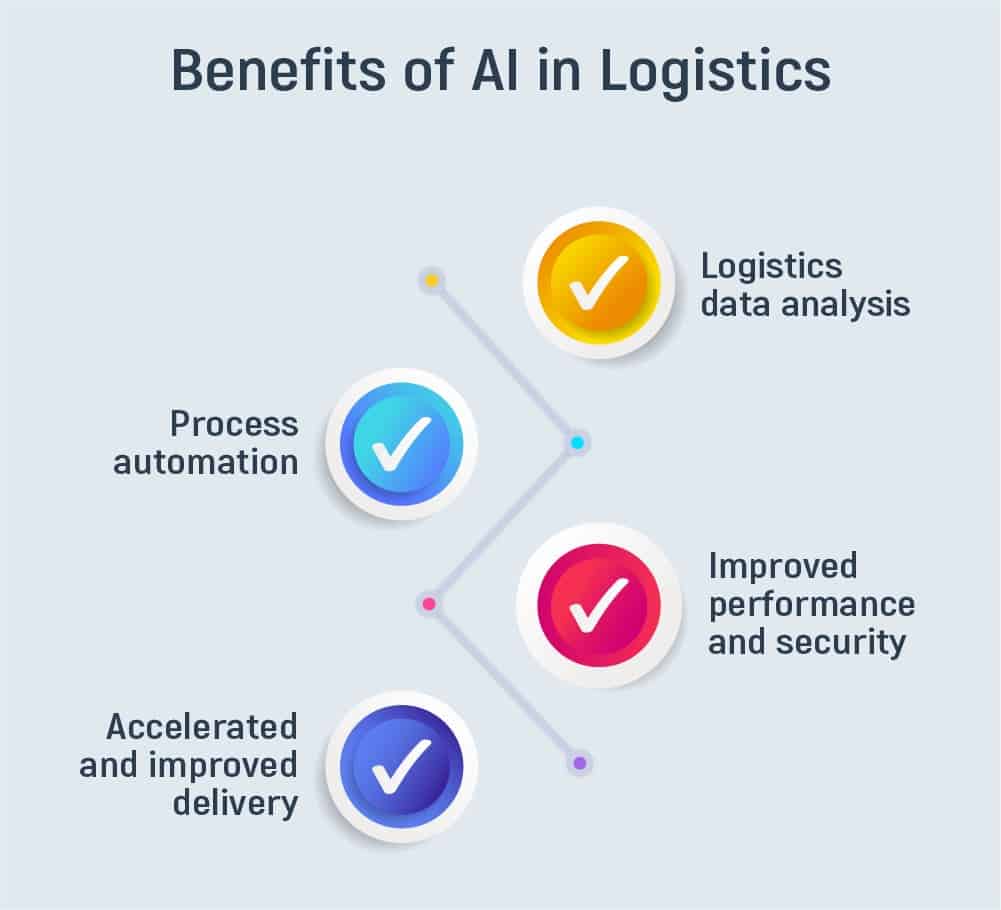

Benefits of AI in Logistics

So far, we’ve talked a lot about the features of the combination of AI and logistics. And the next step is overviewing the advantages of AI in the logistics industry. Here are some of the benefits you get in case of deciding on integrating AI in logistics and transportation:

Logistics data analysis

The research says that 98% of third-party logistics companies believe that data-driven decisions are a must while supplying chain activities, and 71% of those are convinced that big data improves the quality and performance of the process. Artificial intelligence in the transportation industry provides excellent insights and information about resources, delivery and so forth. AI performs a computing technique that selects necessary data pieces and conducts logistics data analysis. In the case of Logistics, data comes from inventory management operations, transportation processes, etc. Thus, logistics analytics turns typical logistics data into truly valuable insights.

Process automation

Companies have recently understood that Big Data in Logistics can help improve logistic automation. Under Big Data in logistics, we understand historical data gathered from processes over the years. Big data tools can not tell exactly what to look for in massive amounts of information since they collect and sort the data without presenting the final solution. Nevertheless, logistics companies have already realized how much structured data they have and how many benefits they could take from data analysis. By automating previously manual processes, AI-powered logistics ensure customers a fantastic experience. Plus, they also enhance internal functional visibility.

Improved performance and security

Human intervention is not enough to establish the correct correlation between large sets of filtered data and continuously analyze them together with daily changing trends and external conditions coming. AI in logistics industry turned out to be a progressive and highly effective fast solution to perform these tasks. There are plenty of conditions like good or bad weather, the impact of geographical location on sales, and logistics.

Let’s take the COVID-19 threat, an unexpected turning point in businesses. AI-based applications help evaluate a lot of data, compare it to external conditions of the same period, and use its intelligence to recommend some actions. The use of AI in logistics provides more efficient planning and warehouse management can improve inventory management with AI, influencing workplace safety data, and informing about any potential risks.

Accelerated and improved delivery

As customers who buy things online, we can not see the scales of modern warehouses with robotic systems. Nevertheless, AI in transport logistics influences the delivery speed, the item’s state, and whether we want to order via that store once again. Artificial intelligent systems decrease the industry’s dependence on human factors and manual measures, which leads to process rapidity, safety, and rationality.

Thanks to delivery automation, it’s much easier to estimate the timing when the goods will reach the delivery targets. The search for a better route, the simplicity of tracking the package, and the usage of aerial transportation to reach different destinations in no time will definitely stimulate the overall delivery process.

Final Thoughts

In the modern age, with an extreme rise in consumption, adopting the latest technologies is one of the most suitable approaches to enhance the supply chain. AI is an excellent way of optimizing processes, and resources and gaining more efficiency. Thus, we can conclude that artificial intelligence for logistics is definitely a decisive move. However, if you still doubt that the combo of logistics and artificial intelligence truly is this superb, the only way to prove it is to see it with your own eyes.

Have a brilliant idea of developing an application of artificial intelligence in logistics? Choose Inoxoft – logistics software development company that provides the best AI and ML solutions on the market. Our dedicated experts focus only on the best project outcomes, considering the client’s needs. We specialize in the use of AI in web development in numerous industries! Feel free to contact us and get the most innovative AI-driven web app to outstand your competitors!

Frequently Asked Questions

Why is machine learning used in logistics?

Machine learning in logistics is used for intelligent route optimization, intelligent sorting and predictive network management. Machine learning models process internal data, understanding different parameters and temporal indicators like departure days, airline performance and predict time delays in air freight shipment.

What’s the role of AI in logistics and supply chain?

AI systems can learn from human decisions, copy data from one system to another, fill in web forms, make judgments, and interact with humans. Thus, Artificial Intelligence in Logistics is designed to see things just like humans, substituting manual time-consuming, repetitive work with automatic machines and reaching several times higher performance.

How is AI transforming the logistics industry?

Artificial intelligence provides a profound data analysis, automated process, accelerated delivery, improved performance, and security. With access to Big Data, logistics AI can also benefit from predictive analytics in making data-driven and well-thought decisions, experience accurate sale estimations for the future, know risks in shipment or discover shortages of which products can happen over a while.