Digitalization has changed a lot of things for people. It gave them many opportunities and significantly eased their lives. Many industries strive to make fast, up-to-date decisions that are going to appeal to many customers. To achieve this goal, companies often use analytics. It helps them perform better and automate services that take too much of employees’ time.

The manufacturing industry is not an exception. This industry is especially productive when all the processes are automated and when the company is using modern solutions. To improve business performance and deliver top-notch services, it’s important to implement manufacturing data analytics. Data analysis in the manufacturing industry is driven by real-time data. Therefore, it is really useful for coming up with new business strategies. Cloud-based analytic platforms process information faster than the human brain, so it’s easier to analyze all the necessary data.

This guide will tell you everything you need to know about analytics in the manufacturing process, why it is beneficial for your business, and why it is necessary to implement. If you feel that this topic interests you, scroll down to learn more!

- What is Manufacturing Analytics?

- What Goals Does Manufacturing Analytics Help Achieve?

- Best Practices for Manufacturing Analytics

- Data Aggregation

- Descriptive Analytics

- Predictive Analytics

- Prescriptive Analytics

- Cognitive Analytics

- Process of Data Collection for Manufacturing Analytics

- Why is It Necessary to Implement Manufacturing Analytics?

- Preventive maintenance

- Demand forecasting

- Price optimization

- Warranty analysis

- Robotization

- Product development

- Computer vision applications

- Consider Inoxoft Your Trusted Partner

- Final Thoughts

What is Manufacturing Analytics?

So the main question is: what is manufacturing analytics? Why is it so important for your business development? Manufacturing analytics is the use of different kinds of data (machine, system, operational) to optimize and manage the production process. Real-time data is really helpful for manufacturers to come up with fast and up-to-date decisions. The way that data is being collected nowadays has significantly improved all the key processes in basically any industry. Human factors often influence the outcome, but when everything is automated, there’s no need to worry about repetitive tasks. Digital transformation has opened the door for accurate decision-making. That’s why manufacturing analytics comes in handy for many manufacturers.

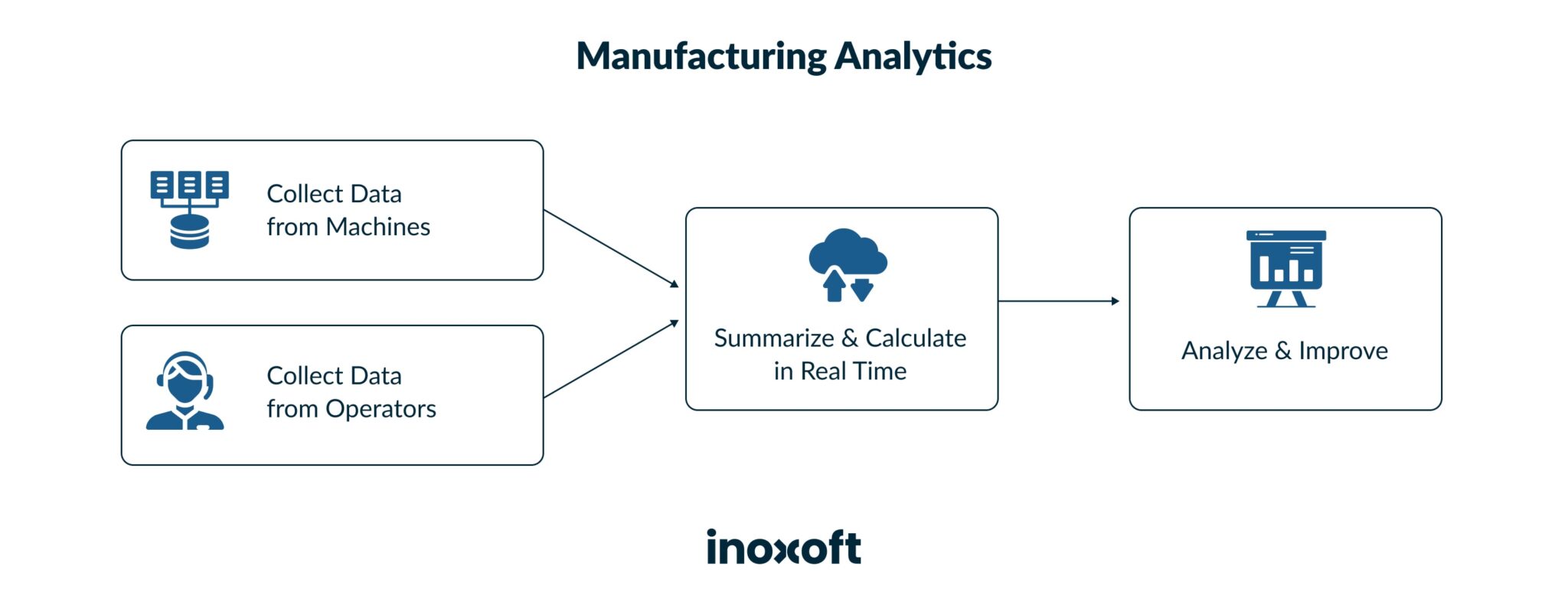

Data analytics in manufacturing allows you to increase equipment utilization, and reduce costs and potential errors. Analytics for manufacturing enhances performance and productivity and ensures product quality. Manufacturing data analysis collects information from machines or operators, summarizes and calculates it in real-time, and only then analyzes and improves it. That’s how analytics in the manufacturing process works. It’s important to notice that analytics for manufacturers is focused on collecting and analyzing data more than controlling processes.

To sum up, data analytics for manufacturing is an important tool for all the modern manufacturers who are interested in creating quality products and coming up with new business ideas. Now that you know manufacturing analytics definition, it’s important to dive deeper and learn more about manufacturing analytics meaning and its practical application.

What Goals Does Manufacturing Analytics Help Achieve?

Manufacturing analytics is truly beneficial for achieving different business goals. The main goal is to be able to use the data in real time, not only have it on display. It gives a better possibility to analyze the data and sort it out. It’s essential to be able to detect all the flaws and issues with equipment and development processes. Manufacturing analytics reduces your costs and possible risks. Any employee can use these insights, and it’s another convenience of manufacturing analytics.

One more goal is to improve the final product look. It’s important to remember that price depends on product quality, so you should pay attention to it. Data-driven product optimization, managing defect density levels and analyzing customer feedback helps to achieve perfection while developing your product. Analyzing product usage can give your company helpful insights on dealing l with components that define usage rates, and whether you should reduce or increase them. Digital factories help your teammates understand the product better and give them fresh ideas on how to improve it.

It’s easy to see how many goals manufacturing analytics helps achieve. It’s a must if you want to save your time and costs, dive deeper into the development process and achieve a high-quality product as a result.

Best Practices for Manufacturing Analytics

Process manufacturing analytics is crucial for improving operational efficiency, product quality, and decision-making.

To harness its full potential, companies should adhere to best practices that help them navigate complex sets of machine data and extract actionable insights. They encompass data collection, integration, analysis, and the application of advanced technologies to drive continuous improvement in the manufacturing process.

Data Aggregation

It’s not a secret that real-time data prevents potential breakdowns. It is essential if you want to avoid all the possible problems. Preventive maintenance programs can predict the likelihood of trouble occurrence, which is beneficial if you tend to plan. This way, technicians don’t have to fix everything post-factum. Hence, it saves your time and costs.

This process is essential for creating meaningful insights and reports. This leads to better decision-making, process optimization, and overall performance improvement in manufacturing operations.

Descriptive Analytics

Descriptive analytics focuses on summarizing historical data to gain insights into past events, trends, and patterns. It provides a foundational understanding of what has happened in a business or operational context.

You may establish a target benchmark for a particular metric, such as energy consumption, expenses, growth, or efficiency. This benchmark is then contrasted with historical data, allowing for identifying potential trends that can inform future decision-making.

Predictive Analytics

Predictive analytics utilizes historical data, statistical algorithms, machine learning, and data mining techniques to predict future events and outcomes. This data is collected from various sources within the manufacturing environment, including sensors, equipment, production logs, and quality control systems.

Predictive analytics in manufacturing enables data-driven decision-making, reduces operational risks, and enhances overall efficiency.

Prescriptive Analytics

Prescriptive analytics is an advanced practice that goes beyond descriptive and predictive analytics. It not only provides insights into what is likely to happen in the future but also offers recommendations on how to optimize manufacturing processes and make better decisions.

Prescriptive analytics handles situations with lots of factors, and even people who aren’t tech experts can use it to figure out how to improve a process or workflow.

Cognitive Analytics

Cognitive analytics combines data analysis with semantics, artificial intelligence, deep learning, and machine learning. As more data is fed into the system over time, it becomes self-improving and self-diagnosing.

Cognitive analytics provides real-time decision support by analyzing incoming data streams from sensors and machines. It enables immediate responses to changing conditions, such as adjusting production scheduling and maintenance.

Process of Data Collection for Manufacturing Analytics

It’s already clear that manufacturing analytics is extremely important in the industry. However, it’s essential to understand the process of collecting data for manufacturing analytics. When you are aware of all the steps you should take, it allows you to understand the process better and fix possible problems that may occur. The process of data collection for manufacturing analytics may seem complicated, but once you consider every aspect of the process, it becomes really clear. Let’s take a look at the manufacturing analytics journey and all its steps.

So what happens during the manufacturing analytics journey? The data you gathered from all the manufacturing data turns into insights, which have lately turned into actions. These actions are meant to affect your business positively.

To start the journey, you need to identify business use cases. The second step is assembling the data. There are often cases when data is mixed up and not ready for analysis at all. It’s important to merge the data, and clean and filter it. This way, it will be ready for analysis. After that, it’s time to start automating the processes. Automation helps you detect all the bugs and defects that are hard to notice if you don’t use technologies.

Now you have explored things and figured out the way things should look at the final. Real-time monitoring applications and dashboards are beneficial and support different types of data. Advanced analytics applications can help you build models for prediction-based analysis you will use in the future. These models are good at predicting equipment failure, production volumes, product quality, and other factors.

Why is It Necessary to Implement Manufacturing Analytics?

Manufacturing process analytics helps solve many development problems. Real-time machine learning has made a lot of use cases possible in manufacturing. It’s important to consider some of them to know all the pros of incorporating manufacturing analytics into your business.

Preventive maintenance

It’s not a secret that real-time data prevents potential breakdowns. It is essential if you want to avoid all the possible problems. Preventive maintenance programs can predict the likelihood of trouble occurrence, which is beneficial if you tend to plan. This way, technicians don’t have to fix everything post-factum. Hence, it saves your time and costs.

Demand forecasting

Demand forecasting allows manufacturers to have full control over the supply chain, resulting in better inventory control. However, demand planning can sometimes be difficult. To make it easier, you can control the supply chain with the help of real-time shop floor data. When manufacturers have a clear vision of the time that is required to do their job, they can estimate their need for material much better.

Price optimization

It’s essential to understand and be able to predict the pricing. You can optimize pricing strategies if you know the time that is required to create parts. It’s important to optimize pricing adequately. If you set them too low, it can negatively affect profitability. However, if you set prices too high, it can reduce demand, which is not what you want to achieve. Analytics for manufacturing makes sure that the prices are set appropriately.

Warranty analysis

Warranty support can be challenging for manufacturers. Sometimes the generalized approach cannot be effective enough, and therefore, many problems can occur later. With the help of manufacturing analytics, you can keep your products’ quality in check and avoid possible breakdowns. Moreover, it prevents future problems and gives you a good understanding of the product’s performance.

Robotization

Digitalization has brought many changes to people’s lives, and robotization is one of these novelties. Now robots can execute all the important tasks without human help. The more advanced these robots are, the more refined is their work. Robots can go into details that are sometimes hard for humans to reach. Thus, robots’ help can be vital for your product’s quality.

Product development

Creating a quality product is not the only important thing for manufacturers. To stay relevant in the market, companies must improve their products and constantly add new features and services. Data science has made it easier to execute these tasks and allowed manufacturers to develop top-notch products.

Computer vision applications

Sometimes it’s difficult for manufacturers to catch all the details while testing the product. That’s why computer vision applications are so necessary. Automation helps you to check all the important aspects of your product and saves you time. In general, computer vision applications are really popular in the manufacturing industry nowadays.

As you can see, manufacturing analytics helps companies solve different business problems. It gives manufacturers a lot of new opportunities and eases their development process. The manufacturing industry requires attention to detail and monotonous work, which is always time-consuming. Automation of processes is always beneficial for employees, as it gives them more possibilities to come up with fresh ideas and refine their projects.

Consider Inoxoft Your Trusted Partner

Inoxoft is an international software development company that provides top-notch software services all over the world. Our dedicated team provides automated processes, high-level customer experience and support. You can be sure that all your requirements and business needs will be fulfilled.

Inoxoft provides Big Data analysis services and AI development services. We will tell you everything about difference between analytics and data science. With the help of our company, you will be able to implement preventive maintenance programs, optimize costs, and forecast possible bugs that can occur.

If you are looking for a devoted partner to help you implement manufacturing analytics, Inoxoft is the best option for you! We will guarantee you not only the best user experience but also a high-quality final product. Contact us and implement manufacturing analytics into your business!

Final Thoughts

Nowadays basically every industry is using a digital approach for their services. Digitalization helps these industries develop and provides many new opportunities. The manufacturing industry requires a lot of attention to detail and patience. That’s why automation of processes and fast performance are so important here. Manufacturing analytics is a must if you want to boost your productivity, produce quality products, and stay competitive in the market.

Manufacturing analytics uses different data to optimize and manage the production process. With the help of data analytics in manufacturing, it’s easier to avoid possible errors, reduce your costs, and save your time. Moreover, it gives you important insights on which products are doing well and which require more of your attention. Manufacturing analytics collects data from machines and operators, summarizes and calculates it in real-time, and then analyzes and improves it. Using data analytics allows you to solve different problems and reach all of your business goals.

It’s difficult to imagine a manufacturing industry without modern technologies. The usage of manufacturing analytics is one more step toward perfect cooperation between people and machines. If you are interested in implementing data analysis in the manufacturing industry, it’s high time you tried it!

Frequently Asked Questions

What is the cost of implementing manufacturing analytics?

The cost of implementing manufacturing analytics depends on many factors. The minimal price is $1000. If you want to know more about analytics for manufacturers, read the article!

What are the main types of data analysis?

There are four main types of data analysis: descriptive, diagnostic, predictive and prescriptive. If you want to know more about roles of these types, scroll up!