Transport business, just like any other business, requires efficiency and precision of all the processes. If there is lack of clever organization, it will take more of your time and costs. Often customers are disappointed with poor logistics services and refuse to cooperate with the logistics companies. Inventory management can improve customer service, decision making and be cost effective. Cloud based technologies are the best option if you need route optimization or route planning. Cloud logistics provides you with up to date features that make freight management and real time fleet management much easier.

The demand for TMS has increased over the years. Of course, off-the-shelf solutions have a lot of things to offer, but even the most advanced readymade logistics software can be not enough for your business needs. That’s why transportation management app development became so popular nowadays.

If you create a transportation management app, will save your costs and make your business the most efficient. Transportation management application development is essential for those who want to meet their business expectations and can’t find the suitable solution among ready-made services. That’s why a lot of companies choose developing a transportation management app, as it is more rewarding for them.

This guide will tell you everything you need to know about logistics and transportation app development, how to build a transportation management application and why transportation software development is a must in logistics industry. If you feel that you are interested, keep on reading!

- What is Transportation Management Software (TMS)

- How does software for the transport management system work?

- Benefits Of Transportation Management Systems

- Enhanced operational efficiency

- Budget optimization

- Better supply chain visibility

- Improved customer service

- Route optimization

- Risk management

- Risk management

- Human error reduction

- Scalability

- Improved collaboration

- Why is it Worth to Develop a Transportation Management App?

- Main Transportation Management App Features

- Customer panel features

- Driver panel features

- Admin panel features

- Why Consider a Custom Transportation Management System Development?

- Driver panel features

- Admin panel features

- The Steps of Building a Transportation Management App

- Customized to specific needs

- Cost savings in the long run

- Smooth integration with third-party systems

- Adaptation to the regulatory standards

- Robust security

- Select the features

- Think about tech stack

- Choose the development team

- Maintain the app

- The Main Technologies of Logistics App Development

- Cost to Create a Management App for Transportation

- Consider Inoxoft Your Trusted Partner

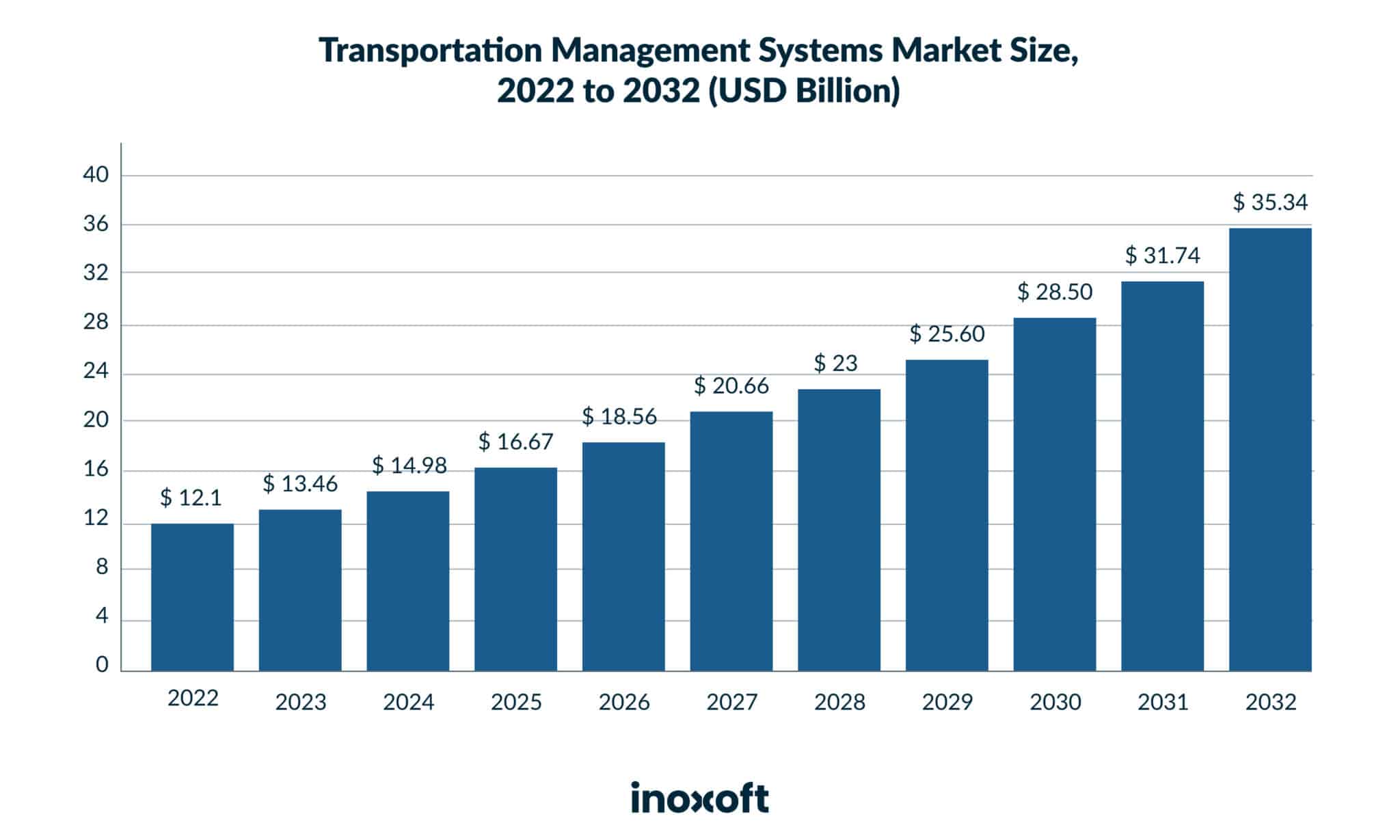

The global TMS market size was valued at 13 billion last year and is expected to expand at a CAGR of 7.24% and reach USD 35 billion in 8 years.

What is Transportation Management Software (TMS)

Firstly, you need to figure out what is a transportation management system. Put simply, transportation management software (TMS) is a subset of supply chain management concerning transportation operations. It uses technology to help companies plan and optimize the physical movement of goods. Its task is also to check if all the documentation is proper. Thanks to building transportation management software, you can track the entire supply chain.

The solutions of transport management are data repositories. They have different features, such as analytical, communication and transactional. Transportation management software can be a part of ERP, or enterprise resource planning, or SCMs (supply chain management system).

Today transportation app development is in high demand.

Companies that decide to create a management app for transportation can execute everyday tasks with ease, such as transporting great amounts of goods. Now supply chains, regulations and transport modes are complicated. It’s almost impossible to solve all the occurring issues without modern technologies. That’s why it is the best decision to make a transportation app.

Automation of the most crucial processes plays a great role in transportation. Transportation management software helps you secure transportation processes without paying excessive costs. TMS also helps you to save quality of all the processes with the chance to increase it.

As you can see, choosing to develop a transportation management tracking app is a great decision. If you want to make your business more efficient and up-to-date, you should consider logistics app development.

How does software for the transport management system work?

TMS serves as a central data repository with transactional, communication, and analytical features. It is often integrated with enterprise resource planning (ERP) platforms and supply chain management systems (SCMs). This integration allows seamless data sharing and communication between stakeholders, including logistic service providers, manufacturers, distributors, and retailers.

And this is how it works:

- When a customer places an order on a website connected to your ERP platform, the order details go to the TMS. The TMS then fetches data about product availability from other systems.

- TMS generates optimal shipping routes, considering delivery windows, load constraints, and real-time traffic conditions.

- The system assists in selecting the most suitable carrier for each shipment. It considers carrier capabilities, pricing, and performance to make the best choice.

- After processing a shipment, TMS provides real-time tracking information. This allows managers to monitor the status of orders, communicate with carriers, and address any issues that may arise during transit.

- It can integrate with CRM modules to give customers status updates on their orders.

Benefits Of Transportation Management Systems

Having a dedicated TMS can safeguard your business against unexpected challenges that may arise in the future. Let’s explore the most essential benefits:

Enhanced operational efficiency

TMS automates many of the tasks that were once done by hand. For example, creating and managing paper-based documents is replaced by digital processes. It means less time spent on paperwork and more on tasks that require human decision-making.

The data provided by TMS is valuable for decision-making. It helps you identify trends and patterns, optimize routes, and adjust schedules based on real-time information. This way, you can run your transportation operations more efficiently.

Budget optimization

With a TMS, you can make your transportation work better and save money. It combines shipments, finding the best routes, and choosing affordable carriers. This way, you spend less on transportation. Also, TMS will find and fix things that are not working well, like trucks returning empty or taking longer routes. So, TMS helps you be efficient and reduces unnecessary expenses.

Adhering to regulations, you avoid fines or penalties resulting from non-compliance. Also, TMS provides accurate data on transportation expenses, allowing for precise budgeting and cost allocation. It helps you manage your financial resources efficiently.

Better supply chain visibility

A TMS provides real-time visibility into your entire transportation process. You can see your shipments, where they’re heading, and when they should arrive. Also, you monitor the performance of carriers, suppliers, and various transportation partners. This data is updated continuously, so you have an up-to-the-minute understanding of your supply chain’s status.

With this real-time information, you can make quick, informed decisions. For example, if a shipment is delayed due to unexpected circumstances, you will immediately adjust schedules or reroute the shipment to minimize disruptions.

Improved customer service

Real-time shipment tracking provides your customers with accurate and up-to-date information about the status and estimated delivery times of their orders. This reduces client uncertainty and frustration. Furthermore, you’ll be aware of any delays or route changes as they happen, promptly informing your customers about any disruptions.

At the same time, TMS allows for more personalized customer service. Tailor your communication and service offerings based on specific needs and preferences. Customers are more likely to return and recommend your business to others when they feel that their needs and concerns are taken seriously and handled efficiently.

Route optimization

TMS uses various factors like delivery time windows, load capacities, carrier capabilities, and real-time traffic data to determine the best routes. This ensures that goods are delivered as quickly and cost-effectively as possible. Such systems efficiently allocate goods to vehicles, ensuring that trucks are not over or underloaded. As a result, you get safer transportation practices and minimized risk of costly fines for overloaded vehicles.

Risk management

Transportation management app development helps businesses comply with specific local regulations and industry standards. It ensures that your operations adhere to legal requirements, reducing the risk of fines and penalties.

For example, it automates the creation of bills of lading, shipping labels, and customs documents. Or incorporate safety and security protocols into transportation processes. These aspects work together to safeguard your operations, reduce risks, and maintain a strong compliance record.

Risk management

Transportation management app development helps businesses comply with specific local regulations and industry standards. It ensures that your operations adhere to legal requirements, reducing the risk of fines and penalties.

For example, it automates the creation of bills of lading, shipping labels, and customs documents. Or incorporate safety and security protocols into transportation processes. These aspects work together to safeguard your operations, reduce risks, and maintain a strong compliance record.

Human error reduction

Manual data entry is prone to errors. With automation, information is accurately captured, reducing the risk of mistakes caused by human input. Also, you’re always working with the most up-to-date data. When decisions stem from accurate and current information, it minimizes errors resulting from outdated or incorrect input. TMS generates shipping labels, bills of lading, and other essential documents automatically. This eliminates the risk of document-related errors, such as incorrect addresses or missing information.

Scalability

TMS is adaptable and can accommodate changes in your business needs. Whether you’re adding new carriers, warehouses, or distribution centers, the system seamlessly integrates these additions into your transportation processes.

Scalability extends to handling fluctuations in demand, including seasonal peaks. TMS can adjust and optimize transportation operations to meet varying demand levels while keeping high service quality. It allows you to accommodate sudden spikes in shipping requirements without disruptions.

Improved collaboration

A TMS serves as a central hub for collaboration, bringing all stakeholders onto one platform. It shares access to crucial information, including shipment details, delivery status, and documentation. Shippers, carriers, and customers can exchange messages and share documents in real time.

Many TMS platforms include automated notifications and alerts. These notifications keep stakeholders informed about critical updates, such as delivery delays or changes in shipment status. As a result, all problems or discrepancies can be addressed immediately.

Why is it Worth to Develop a Transportation Management App?

Now you understand that it’s a good idea to develop a transportation app, because it is really beneficial for your business. Yet, you need to fully understand the reasons why it’s crucial to make a transportation planning software.

First of all, it’s important to notice, that not only logistics company benefit from developing a transportation management app. Basically, any company that deals with supply chains needs to consider implementing TMS. Transportation management app will bring you nothing but conveniences. With the help of it, you can manage warehousing and trucking, fulfill your needs. It will definitely enhance service delivery, making a flow across the supply network smoother. It’s a great chance to optimize supply chain and delivery schedule. This will preserve you from any possible bugs and errors, will give you a possibility to track transit time. As a result, you have a good quality and your costs saved.

If you develop transportation management app, it’s also a possibility to optimize fleet administration and freight dispatching. A lot of employees are put off by boring paperwork, and by developing a transportation management app, they can easily avoid it. Moreover, mobile solutions are really useful, if you want to consolidate data from different sources. This data is later can be used in generating instant reports. Automated processes are a great helper: they free you of boring routine tasks. This is a great opportunity to boost the productivity of your employees. The final argument is, of course, a great customer experience.

Main Transportation Management App Features

Before you start developing your transportation management app, you need to know which features are the most important. Let’s have a look at the main features that any transportation management app should have.

Customer panel features

There are a lot of customer panel features which are really important for the application. One of them is push notifications. They are extremely helpful when the user needs to be alarmed about traffic jams or some incidents which can cause a delay. Messaging is also an important part of the user experience, as they can chat with drivers and solve different issues with them. Sometimes customers may need to book vehicles or schedule trips, and for this purpose there is vehicle booking.

Driver panel features

The next set of features is driver panel features. The first one is map and navigation guidance. The map is integrated into the application, and with the help of it drivers can choose the best route. It prevents drivers from getting lost or going the inconvenient route. The second essential feature is log feature. Drivers can record their daily activity with the help of it. They can track traveled mileage, successfully delivered orders, number of work hours and many other things.

Admin panel features

The last, but not least set of features is admin panel features. One of them is GPS location tracking. Not only admin benefits from this feature, but also driver and a customer. GPS location tracking can help you monitor real-time location of drivers and packages, from the first to the last mile. Offline support is also an essential feature, as often there are times when your customers or drivers are in a location where there is no Internet connection. You should take into account admin dashboard and trip reporting.

Why Consider a Custom Transportation Management System Development?

While off-the-shelf TMS solutions offer convenience, custom software is all about tailored solutions that align precisely with your unique needs and objectives. Let’s overview the benefits of custom transportation management app development:

Driver panel features

The next set of features is driver panel features. The first one is map and navigation guidance. The map is integrated into the application, and with the help of it drivers can choose the best route. It prevents drivers from getting lost or going the inconvenient route. The second essential feature is log feature. Drivers can record their daily activity with the help of it. They can track traveled mileage, successfully delivered orders, number of work hours and many other things.

Admin panel features

The last, but not least set of features is admin panel features. One of them is GPS location tracking. Not only admin benefits from this feature, but also driver and a customer. GPS location tracking can help you monitor real-time location of drivers and packages, from the first to the last mile. Offline support is also an essential feature, as often there are times when your customers or drivers are in a location where there is no Internet connection. You should take into account admin dashboard and trip reporting.

The Steps of Building a Transportation Management App

Now you know the advantages of transportation management application development. Now you need to figure out the steps of building TMS. Let’s have a look at some of them.

Customized to specific needs

Custom TMS solutions are not one-size-fits-all, offering the flexibility and adaptability needed to optimize operations and gain a competitive advantage. With a custom TMS, companies can design the system to precisely match their unique requirements, processes, and workflows. It allows for incorporating specific features and functionalities that address the distinct challenges and opportunities within the company’s transportation and logistics operations.

Cost savings in the long run

Off-the-shelf TMS solutions often come with several features that may be irrelevant to your company. With custom TMS, you don’t pay for unnecessary functions and focus on the most essential improvement areas. At the same time, you don’t have to worry about hidden fees for upgrades, additional support, or feature access.

Custom TMS solutions are an investment in long-term ROI. While the development phase may require more resources, the system’s adaptability, efficiency, and ongoing cost reductions make it a fiscally responsible choice when looking at the bigger picture.

Smooth integration with third-party systems

Off-the-shelf solutions often require businesses to adapt their existing processes to accommodate the software. They potentially lead to compatibility issues, additional costs for system modifications, and a steeper learning curve for employees.

Custom solutions are designed to align with your unique technological landscape, ensuring they effortlessly fit into the existing infrastructure. This results in minimal disruptions to ongoing operations, reduced downtime, and efficient data flow between different systems.

Adaptation to the regulatory standards

Custom solutions are tailored to meet your specific compliance requirements, ensuring seamless alignment with regulatory standards and industry-specific rules. This adaptability not only helps businesses maintain compliance but also reduces the risk of non-compliance penalties and fines.

Custom TMS solutions often include reporting and auditing features that streamline compliance reporting. Detailed audit trails track all transportation and logistics activities, helping organizations demonstrate compliance during audits. Also, such software provides robust security measures and effective documentation management.

Robust security

Custom TMS solutions can be designed with security as a top priority. For example, they implement advanced data encryption protocols and access control to protect sensitive transportation and logistics information.

What’s more, a custom TMS solution can be set up to receive regular security updates and patches to address emerging threats. You can proactively detect anomalies or suspicious behavior, enabling timely responses to potential security incidents.

Select the features

After choosing your target audience and objectives, it’s time to select the best features for your application. You already know some useful features which can be integrated into your app. Yet, the more features you use, the better.

Think about tech stack

Determining the tech stack is the next important step in your app development. You also need to think over some essential integrations, as they can also be useful. Which type of app do you want to develop: a native app, a hybrid app, a web app? These questions will help you choose the right tech stack.

Choose the development team

Software development company can help you develop the application of your dream. Such company can give your team the opportunity to execute other tasks, as they will have less of a burden on their shoulders.

Maintain the app

After all the preparational work and development itself, it is crucial to maintain the app. Don’t forget to improve your application when, so more clients could use it. If you want to stay relevant in the market, this step has a really big value.

The Main Technologies of Logistics App Development

You are closer and closer to meeting your business plan! However, you should consider some technologies of logistics app development. Let’s take a look at some of them.

There are two the most needed technologies for messaging and support: Twilio and Bandwidth. Twilio provides third party API integration, with the help of which you can connect with customers. Bandwidth is basically the cheaper variant of Twilio, but its quality is still high. For authentication you should use Auth0 or OneLogin, which will guarantee you fast onboarding and lots of integrations. Stripe and PayPal are the best for payments gateway, as they provide high checkout conversion. Use MongoDB and MySQL for database management: they are full of up to date features.

For cloud functionality you should pay your attention to Amazon Web Services or Microsoft Azure. Their cloud services are really fast and effective. For frontend development JavaScript, HTML and CSS are the most widely used. These are the most popular programming languages. However, backend development requires programming languages like Node.js, Ruby, Python or Laravel. Python in particular is the language that prioritizes stability, and that’s why it is so beloved by many people. Finally, for mobile app development you should focus on React Native, Iconic and Flutter. They are all appropriate for building cross platform applications.

Cost to Create a Management App for Transportation

The final question is the cost of custom software development for logistics. It goes without saying, that a lot of factors influence the final price of your product. First and foremost, you should take into account the features you want to include. More expensive features are more complex and require more working hours. If you are on a tight budget, you can develop an app that will cost $30 000. However, such app will be lacking a lot of necessary features, and it can cause you some issues.

In general, the average price of transportation management app is approximately $50 000. Keep in mind, that application like this has an average amount of features, enough for fulfilling your clients’ needs. If you want to make your app really complex and feature-heavy, be ready to spend more money: from $100 000 to $150 000. All these costs are only for transportation management app development, but there are also such important moments as onboarding, recruitment and so on. If you are interested in making the process more cost-effective, you can use an offshore goods transport app development, as it is really useful for those who want to avoid some extra expenses.

Before you start to consider adding some features, you need to start from minimum viable product, or MVP. With the help of it, you can gather a lot of feedback from your customers, and only then make some decisions considering your application. You can make your app richer and more feature-heavy, in case the client is interested in it. Such a draft of your future application requires very little money, roughly $10 000-$15 000. During the trial period, you can see what interests your customers the most and what is in demand for them.

Consider Inoxoft Your Trusted Partner

Inoxoft is a software development company that offers top-notch modern services for clients all around the world. Our dedicated team is always ready to help you form your vision and meet all your business requirements.

Inoxoft provides application development solution, web application development services and customizable inventorization solution. With the help of our company you will know more about centralized distribution system development.

Transportation management application development can be challenging, but Inoxoft makes the whole process rewarding and interesting. If you are looking for a reliable partner, our company is exactly what you are looking for. Contact us, and we will help you develop an application of your dream!

Frequently Asked Questions

What is TMS software?

Transportation management software (TMS) is a subset of supply chain management concerning transportation operations.

What is transportation app development cost?

The price of logistics app development can depend on many things, for example, the amount of features you want to incorporate. Overall, the average cost of transportation app development is $50 000.

What are the main steps of transportation management application development?

To build a transportation management app, you need to choose the type of app you want to develop, determine your target audience, select the features, choose the tech stack and development team and, of course, maintain the app.