Web App for Printing Customized 3D Models for Surgery Supply

The process from requesting 3D models to real surgery takes a long time due to

- a wide range of mandatory workflows and internal processes in medical institutions.

- hierarchy in document management.

The idea was to create a convenient solution that would help clinics and 3D design companies easily communicate, build workflows, share files, and sign e-documents to speed up the whole process.

Inoxoft delivered a responsive web platform and implemented a custom 3D viewer that helps clinics and 3D design companies communicate, reduce paperwork, and human factor errors, and speed up the time of each project by providing an accessible responsive web platform developed from scratch.

The solution ensures:

- Accurate procedure execution

- 3D pre-planning of surgical operations

- Precise organ reconstruction

- Reduced surgery and time costs

Inoxoft’s solution enables clinics and 3D design companies to communicate, reduce paperwork and human factor errors, and speed up the time of each project by providing an accessible responsive web platform developed from scratch.

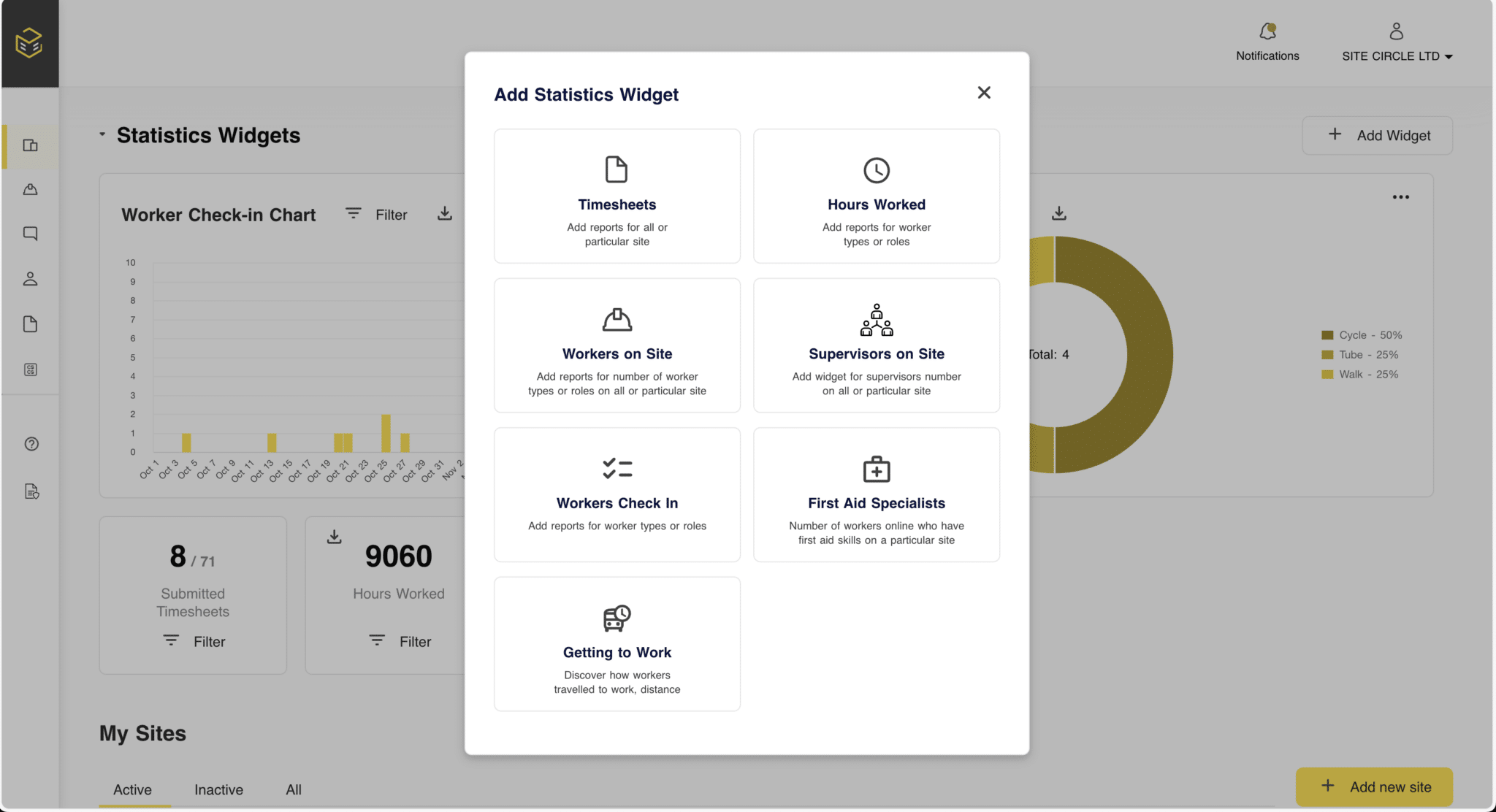

- 3D Viewer

- Admin Dashboard

- Payment Module (all invoices and payment info of all projects)

- Calendar view with the appointments

- Few levels of permissions

- Messenger

Full Story

Inoxoft solution

The technological innovations in recent decades don’t miss the world of medicine, and one of the interesting uses of technology today is the 3D printing of organs. More specifically, accurate 1:1 scale models of body parts.

The process is time-consuming and requires lots of attention and paperwork. In this particular area every minute counts so together with our client we delivered a solution that ensures spending up those processes.

When a patient is diagnosed with a disease and needs a partial organ replacement, a clinic turns to Synergy3dMed to make a Personalized Surgical Kit - a model of the diseased organ with all fixing elements (e.g. bone)

Synergy3dMed registers a clinic and gives access to the web platform (all further interactions will be conducted within the platform), creates a new appropriate workflow, and grants stakeholders roles and permissions accordingly.

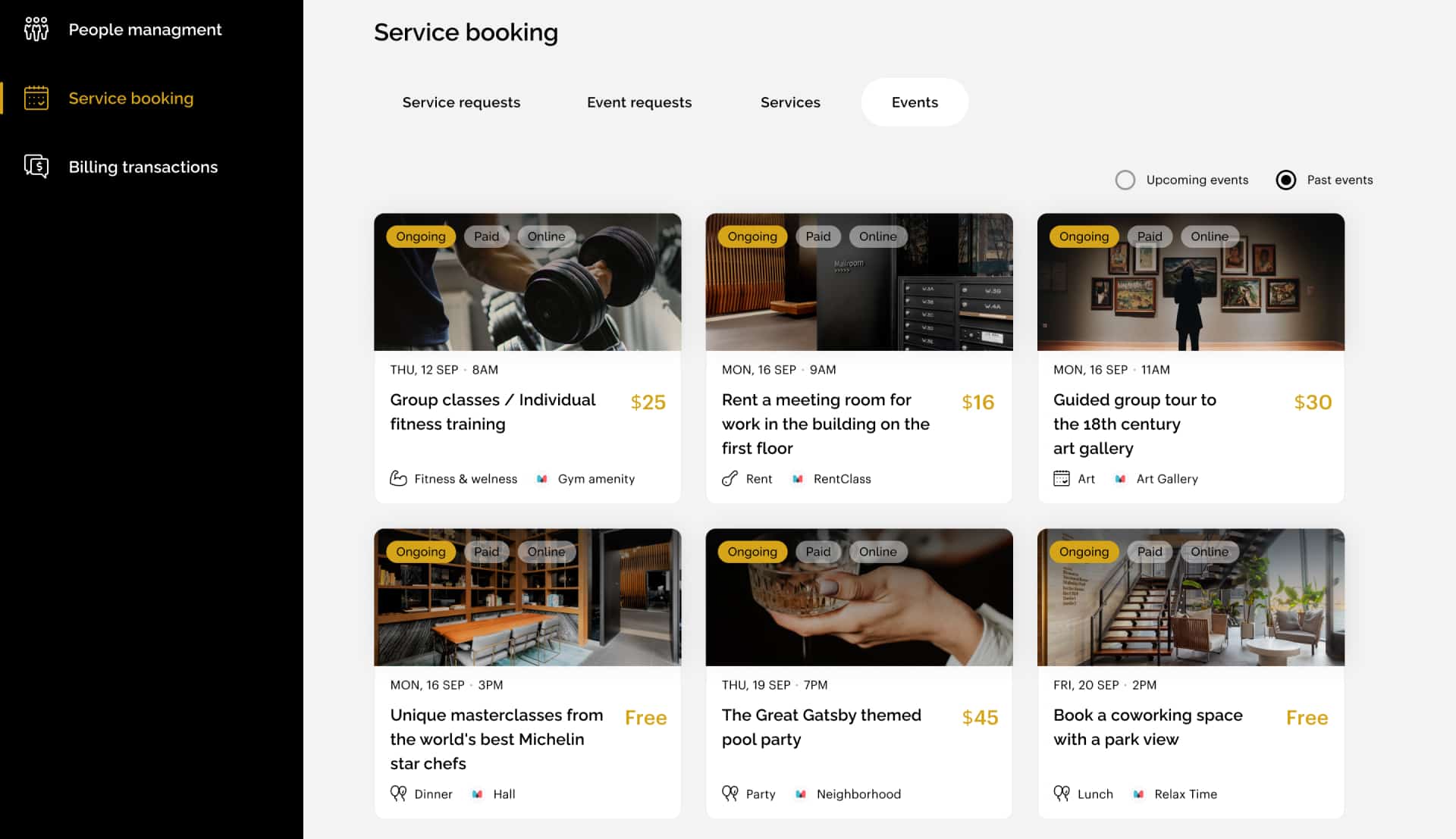

Using a web platform all stakeholders can customize workflows,user-roles and interact through the following tools:

- chat

- communication stream

- video calls,

- ScreenShares

- calendar (scheduling & conducting meetings, reminders)

- mail notifications

- e-Signature

- files converter

Then a doctor uploads the outbound data regarding the required replacement (CTMRI)

Inoxoft’s team developed a custom 3D viewer, so a designer can convert CT/MRI into a 3D model of the implant and sends it back to the clinic.

After the doctor simulates the surgery procedure and makes needed adjustments to the 3D model, which are later implemented by the designer. Throughout this iterative process designer and doctor communicate and validate corrections within the platform. The designer provides stakeholders with the final version of the 3D model to get approval via e-signature.

Once a personalized Surgical Kit is printed, it is tested and sterilized. All the stakeholders give approvals using e-signature after each step is completed.

Results

Inoxoft delivered a comprehensive user-friendly web application with

- 3D Viewer

- Customizable permission settings for every user

- Ability to track the process of legal documents approvals

- Legal documents templates with the ability to modify them

- File uploading, cloud storage, and sharing

- Workflow management dashboard personalized for each clinic

- QA module for tracking the alignment of the current workflow with the defined one