Enterprise Resource Planning (ERP) is a game-changer, seamlessly managing business processes across industries. From logistics optimization to cost reduction, this article delves into the diverse facets of ERP, shedding light on its significance and practical applications.

What is the essence of ERP, and how does it revolutionize business management? Uncover the answers to these questions for a comprehensive understanding.

Key Takeaways:

- Enterprise Resource Planning (ERP) streamlines core business processes for varied industries.

- ERP types include Cloud, On-premise, and Hybrid, each with distinct advantages.

- ERP enhances shipping logistics, automating documentation and ensuring control.

- Custom ERP software in logistics boosts integration, cuts costs, and ensures data security.

- What is Enterprise Resource Planning (ERP)?

- Role of ERP in the Logistics and Shipping Areas

- How ERP Software Can Improve Your Logistics Management?

- Increased integration, collaboration and interaction

- Available business information

- No need for manual reporting

- Automated business processes

- Reduction of operational costs

- Data security

- The Main Modules of ERP Software

- Finance

- Procurement

- Manufacturing

- Inventory management

- Order management

- Warehouse management

- Supply chain management

- Customer relationship management

- Professional services automation

- Workforce management

- Human resources management

- eCommerce

- Marketing automation

- Process of ERP Software Development

- Define your goals and expectations

- Discuss it with your team

- Start wireframing

- Design

- Develop and test

- Deploy

- Why You Should Choose Custom ERP Software

- Technology for an ERP System Development

- Cost of Custom ERP Software

- Inoxoft Provides a Custom Software Development for Logistics

What is Enterprise Resource Planning (ERP)?

The first question that comes to mind is: “What is Enterprise Resource Planning?”. Put simply, Enterprise Resource Planning (ERP) is the integrated management of main business processes. ERP is used to manage everyday business activities.

There are three main types of Enterprise Resource Planning: cloud ERP, on-premise ERP and hybrid ERP. On-premise ERP is expensive, but secure and gives you full control. Cloud ERP is the most affordable and up to date, but has limited customization. Hybrid ERP is really flexible, but expensive and difficult to implement.

Enterprise Resource Planning is used in many industries, such as IT, manufacturing, construction, electronics and technology, healthcare, fashion, retail and so on. ERP is really flexible and adaptive to the needs of different industries, that’s why it is so popular among them. Enterprise Resource Planning allows these industries to execute their daily tasks easily, saving money and costs.

Role of ERP in the Logistics and Shipping Areas

The role of ERP software development for shipping is really difficult to overestimate. One of the most challenging moments in the logistics is documentation. It’s really important to keep everything in check. ERP software development for shipping and logistics allows you to generate the documentation in one click, which is really convenient.

Developing an ERP system for shipping is crucial for control over every process, as they all should be streamlined at the right time without any delays. If you need to provide some information or guides, ERP is an ultimate choice. You can use ERP to maintain records of food and fuel provision.

One more benefit of Enterprise Resource Planning is the ability to have other systems integrated in ERP management tool. Moreover, there is also a high chance of mistake made by human. With ERP you don’t have to worry about bugs and errors.

How ERP Software Can Improve Your Logistics Management?

There are many reasons why you should create a custom ERP software for delivery-related business. Before you make an ERP software in logistics, you should know all the benefits you get. Here are some of them:

Increased integration, collaboration and interaction

It’s crucial to be able to collaborate with different departments. Development of an ERP software for shipping makes the process transparent for all the coworkers.

Available business information

Another benefit is availability on any device. Moreover, you can compare and analyze different departments’ performance and decide what should be improved.

No need for manual reporting

Managing spreadsheets is routine work that takes a lot of time and energy. With ERP you can forget about this mundane work, as all the data is collected and sorted out automatically.

Automated business processes

Talking about automatization, all the routine work doesn’t let you evolve and improve your productivity. If you build a custom ERP software for shipping, this problem disappears.

Reduction of operational costs

When you are using ERP software, all the bottlenecks are visible. It allows your team to change their strategy and adjust to current situation.

Data security

Of course, one of the most important factors is data security. When you develop a custom Enterprise Resource Planning software for shipping and logistics, you can be sure that your data is safe.

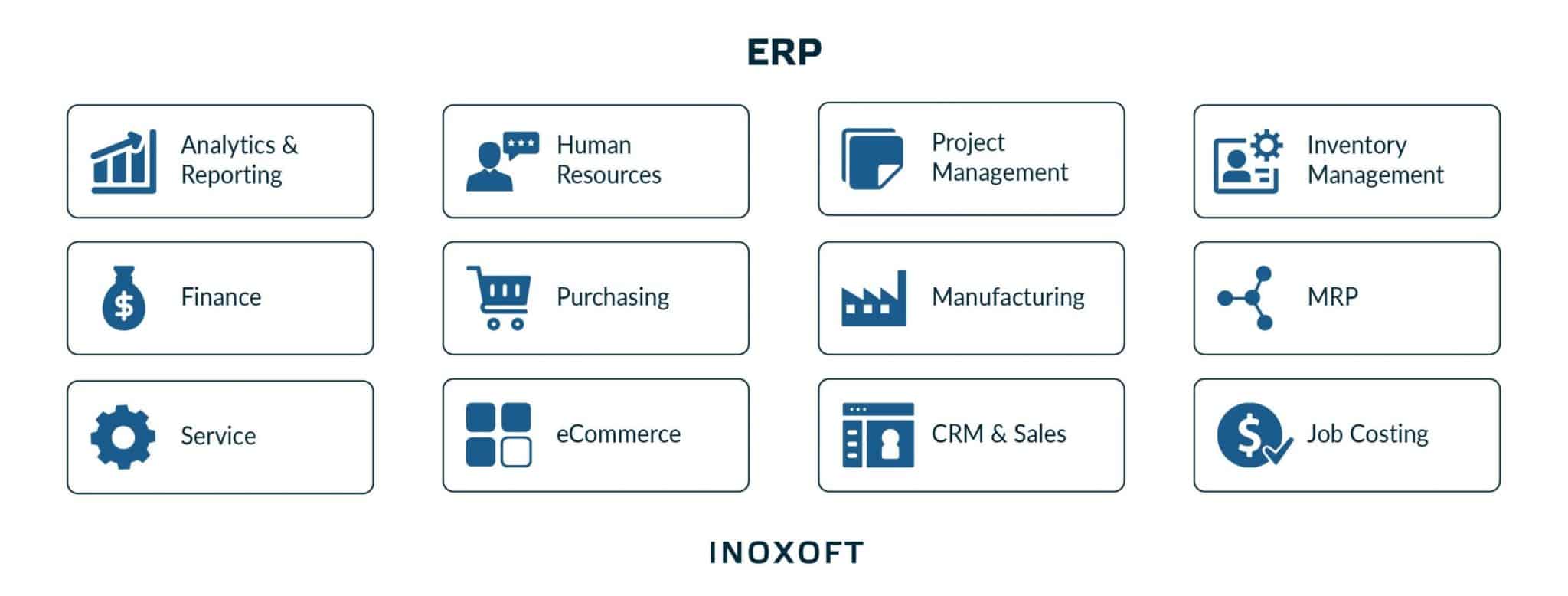

The Main Modules of ERP Software

Before you learn how to build an ERP system for shipping from scratch, you should know the main modules and functions which should definitely be included in ERP software. Here are some of these features:

Finance

With the help of this module you can have a clear vision of your financial state and have an outlook on future income.

Procurement

It’s essential to be able to secure the materials which are used for manufacturing and selling. Procurement module is responsible for this.

Manufacturing

Manufacturing is an integral part of Enterprise Resource Planning. With time the approach to manufacturing improves and becomes more up to date.

Inventory management

Inventory management enables you to track the location of a shipping and control item quantities. It is also beneficial when you need to calculate your costs.

Order management

The task of this module is to track orders from receipt to delivery. You can also choose the most cost-fulfilling solution for fulfilling an order.

Warehouse management

Businesses who run their own warehouses might get a quick return on investment by using a warehouse management module.

Supply chain management

This module tracks every step of the supplies’ movement through the supply chain. Moreover, you can control the goods which were returned for this or that reason.

Customer relationship management

Customer relationship management provides all the prospect and customer information. You can get to know your clients better and figure out what interests them.

Professional services automation

The company plans and manages projects with the help of this module. It is also widely used by services-based organizations.

Workforce management

If you want to know more about your employees’ productivity, this module is exactly for you. It’s a great chance to boost the performance of the whole company.

Human resources management

It’s important to know your coworkers, that’s why this ERP module stores all the essential information about your employees.

eCommerce

If your company needs to launch a business-to-business or business-to-consumer eCommerce website. You can change and update the look of website however you want with the help of special tools.

Marketing automation

All the marketing campaigns are automated, and it’s a great way to choose the best marketing strategies and make some future marketing decisions.

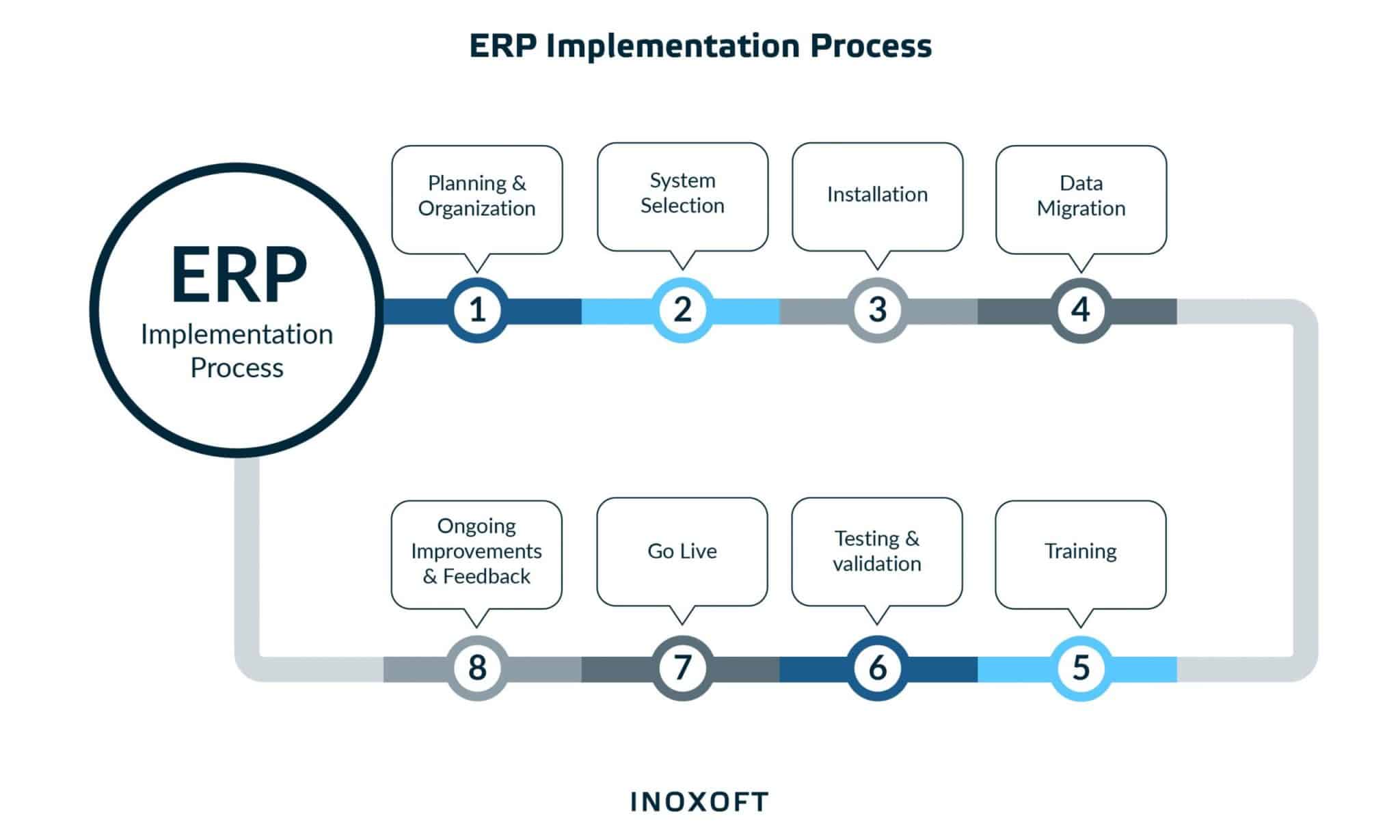

Process of ERP Software Development

Now you know all the benefits ERP development brings you. Let’s have a look at all the steps of ERP development process.

Define your goals and expectations

Before you start, you should figure out which processes should be improved, why do you need an ERP system and who is your target audience.

Discuss it with your team

To make the perfect project, you need to consult with your teammates. They will help you come up with new creative ideas.

Start wireframing

Wireframing means choosing the exact number of modules, essential resources, estimated man-hours and the timeframe.

Design

It’s crucial to choose the right visual for your ERP. If it is appealing for the eye, it will definitely attract more customers.

Develop and test

When all the preparational steps are finished, it’s time to develop an ERP system. After that it’s important to test and improve your product.

Deploy

The last step is deployment, which means that your company starts benefiting from the implementation of the ERP system.

Why You Should Choose Custom ERP Software

You can use off-the-shelf ERP, but it’s more rewarding for you to choose custom ERP software. Off-the-shelf software provides you with readymade solutions, and custom ERP requires more effort.

You should consider custom ERP, as it easily adapts to your business needs. When you are developing custom ERP, all your costs are upfront, and a lot of organizations appreciate it. Moreover, it’s easier to manage all the processes.

Technology for an ERP System Development

The best frontend technologies for ERP development are AngularJS, React and Vue.js; the best backend technologies are Java, .NET, Node.js and Python. Ultimate database management systems are MySQL, mongoDB and Oracle. Finally, you should choose AWS, Google Cloud and Azure cloud providers. With the help of these technologies you can develop top-notch ERP system.

Cost of Custom ERP Software

The important part before the development is estimating your budget. The cost of ERP software is influenced by a lot of factors. Project complexity, development team, region and seniority level have a big impact on the price of ERP software. The more complicated your project is, the higher the price is. The people you choose to work with can also influence the cost, so choose your team members carefully.

Inoxoft Provides a Custom Software Development for Logistics

Inoxoft is a software development company that offers top-notch services for clients all around the world. Our dedicated team will help you meet all your business needs.

Inoxoft provides custom software development for logistics, software product development services for startups and ERP for real estate industry. You can also learn more about AI in logistics examples.

You can rely on our company in developing the best ERP software for shipping and logistics solution. Contact us, and we will help you make your business plans come true!

Frequently Asked Questions

Why do you need to create a custom ERP software for delivery-related business

It's important to create a custom ERP software for your business, as it streamlines your organization, puts your data in one place, saves your time and costs.

Is it necessary to customize an ERP software for shipping?

Customized ERP easily adapts to your business needs and allows you to manage all the processes. That's why customized ERP is more preferable than ready-made one.

What is the cost of a custom ERP systems?

The cost of ERP depends on many things: project complexity, development team, region and seniority level. If you want to know more, read the article!