Manufacturing is an industry that continues to embrace technological advancements in order to streamline processes and increase efficiency. One such advancement that has gained significant traction is Artificial Intelligence (AI). In this article, we will delve into the various use cases of AI in manufacturing, understand its basics, explore specific applications, discuss its benefits and challenges, and look into the future of Artificial Intelligence in this industry. At Inoxoft we recognize the importance of AI in manufacturing and have helped numerous organizations integrate AI solutions into their operations.

- Understanding the Basics of AI in Manufacturing

- The Intersection of AI and Manufacturing

- How AI is Transforming the Manufacturing Landscape

- The Impact of AI on Manufacturing Efficiency

- Specific AI Applications in Manufacturing

- AI in Quality Control and Inspection

- AI in Predictive Maintenance and Machinery

- AI in Supply Chain and Inventory Management

- The Benefits and Challenges of AI in Manufacturing

- Advantages of Implementing AI in Manufacturing Processes

- Potential Drawbacks and Risks of Artificial Intelligence in Manufacturing

- The Future of Artificial Intelligence in Manufacturing

- Emerging Trends in Artificial Intelligence for Manufacturing

- Predictions for AI's Role in Future Manufacturing

- Final Thoughts

Understanding the Basics of AI in Manufacturing

Before we dive into the specific use cases, it is essential to define AI and its relevance in the manufacturing sector. AI refers to the simulation of human intelligence in machines that are programmed to think and learn like humans. In manufacturing, AI utilizes advanced algorithms to analyze vast amounts of data, recognize patterns, make predictions, and automate tasks, all with the aim of enhancing operational efficiency.

But what exactly does this mean for the manufacturing industry? Let’s take a closer look.

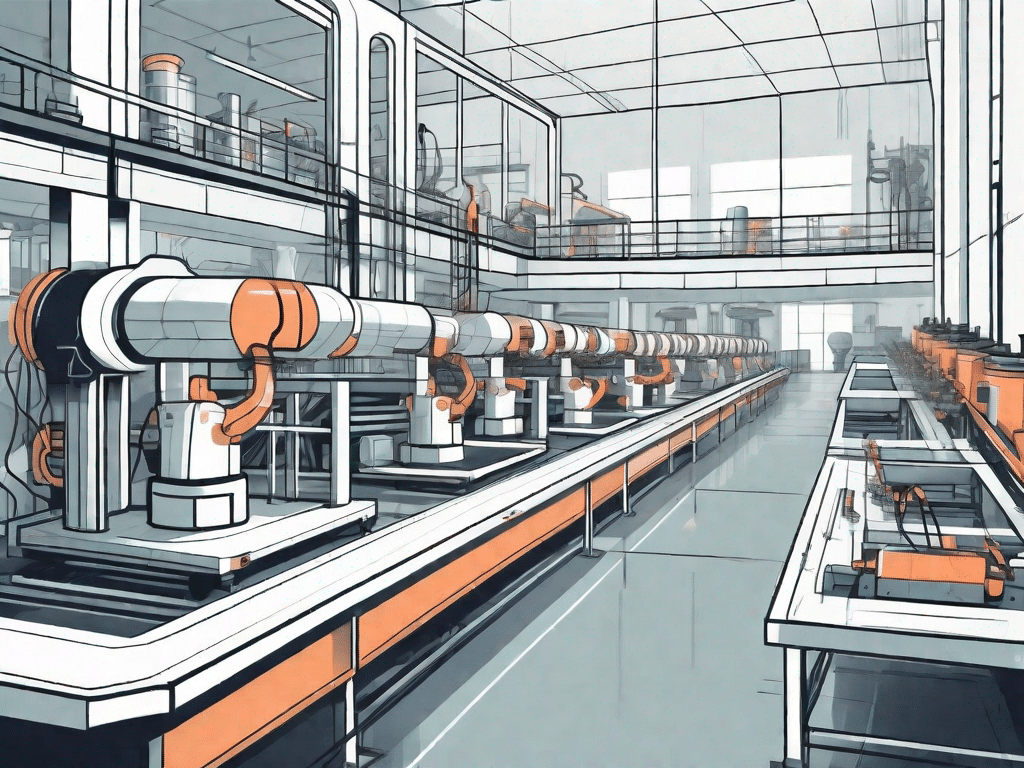

One of the key roles of AI in modern manufacturing is to enable machines to interact and communicate with each other, leading to what is known as the Internet of Things (IoT) or Industry 4.0. This integration of AI, IoT, and the industrial internet allows production facilities to create interconnected systems that can optimize production, minimize downtime, and improve product quality.

Imagine a factory where every machine is connected to a central AI system. These machines can communicate with each other in real-time, sharing information about their performance, maintenance needs, and production schedules. This interconnectedness allows for greater efficiency and productivity.

For example, let’s say a machine on the production line starts to show signs of wear and tear. With AI and IoT in place, the machine can automatically send a notification to the maintenance team, alerting them to the issue. The maintenance team can then schedule a repair before the machine breaks down, minimizing downtime and preventing costly delays in production.

Furthermore, AI can analyze the vast amount of data collected from these interconnected machines to identify patterns and make predictions. This predictive analysis can help manufacturing companies optimize their production processes by identifying bottlenecks, predicting equipment failures, and even forecasting demand.

By leveraging AI, including computer vision, manufacturers can also improve quality standards. algorithms, particularly those in computer vision, can analyze data from various sources, such as sensors and cameras, to detect defects or anomalies in real-time. This allows manufacturers to take immediate action, ensuring that only high-quality products reach the market. The ability to employ computer vision algorithms enhances the precision and effectiveness of defect detection in the manufacturing process.

Another significant benefit of Artificial Intelligence in manufacturing businesses is the ability to automate repetitive and mundane tasks using AI solutions. By offloading these tasks to AI-powered machines, workers can focus on more complex and creative aspects of their jobs. This not only improves job satisfaction but also increases overall productivity.

In conclusion, Artificial Intelligence, along with AI tools, has become indispensable in the manufacturing industry. Its ability to analyze data, automate tasks, and enable machine-to-machine communication has revolutionized the way manufacturers operate. With Artificial Intelligence and IoT working hand in hand, manufacturers can achieve higher efficiency, improved product quality, and ultimately, a competitive edge in the market.

The Intersection of AI and Manufacturing

Advanced manufacturing technologies in AI have been particularly transformative for the manufacturing landscape. AI technology has the potential to revolutionize traditional manufacturing processes and pave the way for smarter, more efficient factories. Let’s explore how AI is transforming the manufacturing industry.

How AI is Transforming the Manufacturing Landscape

Automated systems, particularly those incorporating computer vision, are being deployed to monitor and control various aspects of smart manufacturing, leading to increased productivity and reduced costs. For example, smart algorithms, including computer vision capabilities, can analyze real-time data from sensors installed throughout the manufacturing floor to detect anomalies and identify potential issues before they escalate into major problems.

Moreover, AI is not only limited to the detection of issues but also plays a crucial role in optimizing the entire manufacturing process. By analyzing vast amounts of data, smart algorithms can identify patterns and trends that humans may overlook, leading to more efficient production methods. This data-driven approach allows manufacturers to make informed decisions and streamline their operations.

Additionally, AI-driven robots, equipped with machine learning algorithms, have become increasingly common in manufacturing facilities. These robots are capable of performing intricate tasks with precision and speed, resulting in improved manufacturing quality and reduced errors. They can also adapt to changing production requirements, thereby enhancing flexibility in manufacturing process.

Furthermore, AI is not just limited to the physical aspects of manufacturing. It is also transforming the way manufacturers interact with their customers. AI-powered chatbots and virtual assistants, utilizing machine learning, are being used to provide personalized customer support, answer queries, and even assist in product customization. This level of automation and personalization, driven by machine learning, enhances the overall customer experience and helps manufacturers build stronger relationships with their clients.

The Impact of AI on Manufacturing Efficiency

By automating repetitive tasks and optimizing processes, AI helps manufacturers improve operational efficiency. For instance, machine learning algorithms can optimize production schedules based on real-time data, ensuring that resources are allocated effectively and minimizing idle time. This not only reduces costs but also increases overall production output.

Moreover, AI based systems also play a crucial role in predictive maintenance. By analyzing historical data and identifying patterns, cognitive computing systems can predict when machines are likely to fail and proactively schedule maintenance activities. This preventive approach minimizes unplanned downtime and maximizes equipment lifespan, which is cost effective for manufacturers.

In addition to optimizing production and maintenance, AI is also transforming supply chain management in the manufacturing industry. Machine learning algorithms can analyze vast amounts of data from various sources, such as sales forecasts, inventory levels, and supplier performance, to optimize inventory management and ensure timely delivery of raw materials. This level of robotic process automation and data-driven decision-making improves supply chain optimization and reduces costs.

Furthermore, AI is also being used to enhance quality control processes in manufacturing. Machine-driven systems can analyze product data, such as images and sensor readings, to detect defects and anomalies that may not be visible to the human eye. This level of precision and accuracy in quality assurance ensures that only the highest quality products reach the manufacturing market, enhancing customer satisfaction and brand reputation.

In conclusion, AI is revolutionizing the manufacturing industry by improving productivity, reducing costs, enhancing operational efficiency, and transforming customer interactions. As AI continues to advance, we can expect even more innovative applications and transformative changes in the manufacturing landscape.

Specific AI Applications in Manufacturing

Now that we have a better understanding of how AI is transforming the manufacturing industry, let’s explore some specific use cases, including manufacturing examples, where AI has proven to be highly impactful.

AI in Quality Control and Inspection

Quality control is a critical aspect of manufacturing, as it ensures that products meet the required standards. Technology-driven systems can analyze images and videos captured during production to detect any defects or anomalies. By automating this process, manufacturers can significantly reduce the time and effort required for manual inspections, while also improving accuracy and consistency.

For example, in the automotive industry, computational intelligence programs can analyze paintwork for any imperfections, such as scratches or uneven coating. This level of precision ensures that every vehicle leaving the assembly line meets the highest quality standards, enhancing customer satisfaction and brand reputation.

In the electronics industry, AI, empowered by machine learning algorithms, can detect microscopic defects in circuit boards that may not be visible to the human eye. This capability is especially crucial for quality control inspections, as AI identifies and addresses issues early in the manufacturing process, preventing faulty products from reaching the market and saving both time and resources.

AI in Predictive Maintenance and Machinery

AI in Supply Chain and Inventory Management

The efficient service management of the supply chain is crucial for manufacturers to meet customer demands and minimize costs. AI-powered systems can analyze historical data and external factors to predict demand and optimize inventory levels. By accurately forecasting demand, manufacturers can avoid stockouts and overstocking, ensuring a smooth flow of materials and reducing holding costs.

In the food and beverage industry, AI, powered by machine learning algorithms, can analyze various factors, such as weather patterns, social media trends, and historical sales data, to predict consumer demand for specific products. This integration of machine learning enables manufacturers to adjust production and inventory levels accordingly, ensuring that popular items are always available on store shelves and optimizing supply chains.

In the pharmaceutical industry, AI can help optimize the supply chain by analyzing data on drug demand, production capacity, and transportation logistics. By identifying bottlenecks and inefficiencies, manufacturers can streamline their operations, reduce lead times, and ensure that life-saving medications reach patients in a timely manner.

The Benefits and Challenges of AI in Manufacturing

Advantages of Implementing AI in Manufacturing Processes

Integrating AI in manufacturing can lead to significant benefits. Technology-driven systems can optimize production, reduce waste, and improve product quality, resulting in higher customer satisfaction. For example, deep learning models can analyze vast amounts of data in real-time, identifying patterns and trends that humans may miss. This enables manufacturers to make proactive decisions and adjustments to their production processes, ensuring optimal efficiency and minimizing errors.

In addition to improving production processes, AI also enables manufacturers to make data-driven decisions. By collecting and analyzing data from various sources, such as sensors, machines, and supply chain systems, AI can provide valuable insights that help manufacturers allocate resources more efficiently. This, in turn, leads to cost savings and improved profitability.

Furthermore, AI can enhance workplace safety by automating dangerous or repetitive tasks. For instance, robots equipped with AI algorithms can handle hazardous materials or perform monotonous tasks that may pose risks to human workers. By reducing the need for human intervention in such tasks, manufacturers can significantly decrease the risk of accidents and injuries, creating a safer work environment.

Potential Drawbacks and Risks of Artificial Intelligence in Manufacturing

While AI has immense potential in manufacturing, there are certain challenges that must be considered. One such challenge is the initial investment required to implement AI systems. The cost associated with AI infrastructure, software development, and staff training can be significant. However, it is important to note that the long-term benefits and cost savings resulting from AI implementation often outweigh the initial investment.

Additionally, there may be concerns surrounding data privacy and security when implementing automated systems. As AI relies on vast amounts of data, manufacturers must ensure that adequate measures are in place to protect sensitive information. This includes implementing robust cybersecurity protocols, regularly updating software and hardware, and providing comprehensive training to employees on data privacy best practices.

Moreover, the integration of Artificial Intelligence in manufacturing may also raise ethical concerns. For instance, there may be debates surrounding the impact of Artificial Intelligence on employment. While Artificial Intelligence can automate certain tasks, potentially reducing the need for human workers, it can also create new job opportunities that require specialized skills in managing and maintaining AI systems. Striking the right balance between robotic process automation and human labor is crucial to ensure a sustainable and inclusive workforce.

In conclusion, integrating Artificial Intelligence in manufacturing processes offers numerous benefits, including optimized production, improved product quality, data-driven decision-making, cost savings, and enhanced workplace safety. However, manufacturers must also address challenges such as the initial investment, data privacy and security, and ethical considerations. By carefully navigating these challenges, manufacturers can harness the power of AI to drive innovation, efficiency, and competitiveness in the manufacturing industry.

The Future of Artificial Intelligence in Manufacturing

Emerging Trends in Artificial Intelligence for Manufacturing

Augmented Reality (AR) and Virtual Reality (VR) technologies are expected to play a more significant role in manufacturing. These technologies can enhance training and product development, as well as improve worker safety and productivity. For example, AR can be used to overlay digital information onto physical objects, allowing workers to see real-time instructions or visualize complex assembly processes. VR, on the other hand, can create immersive simulations for training purposes, enabling workers to practice their skills in a virtual environment before applying them in the real world.

In addition to AR and VR, the use of Artificial Intelligence in predictive analytics and demand forecasting is expected to become more prevalent in the manufacturing industry. By analyzing large volumes of data, intelligent algorithms can identify patterns and trends that humans may overlook. This enables manufacturers to make data-driven decisions in real-time, optimizing production schedules, inventory management, and supply chain operations. With AI-powered predictive analytics, manufacturers can anticipate market demand, reduce waste, and ensure timely delivery of products to customers.

Another emerging trend in AI for manufacturing is the adoption of collaborative robots, also known as cobots. These robots are designed to work alongside workers, assisting them in repetitive or physically demanding tasks. Cobots are equipped with sensors and AI algorithms that allow them to adapt to their environment and collaborate safely with humans. By automating certain tasks, cobots can increase productivity and free up humans to focus on more complex and creative aspects of manufacturing.

Predictions for AI’s Role in Future Manufacturing

In the future, AI is likely to permeate every aspect of the manufacturing industry. From design and production to logistics and customer service, smart factories leveraging AI-powered systems will become the norm rather than the exception Manufacturing companies who leverage the potential of AI will be able to gain a competitive edge by improving efficiency, enhancing product quality, and unlocking new revenue opportunities.

AI will revolutionize the design process by enabling engineers to create more innovative and optimized products through AI-based product development. By analyzing vast amounts of data and running simulations, smart algorithms can suggest design improvements, identify potential flaws, and optimize product performance. This not only accelerates the design process but also ensures that products meet the highest standards of quality and functionality.

Furthermore, autonomous robots, AI-powered robots, and automation systems, surpassing human capabilities, will transform the production process. These systems can autonomously perform complex tasks with precision and speed, reducing the risk of errors and improving overall productivity. By integrating AI into assembly lines, a manufacturing company can achieve higher levels of efficiency, minimize waste, and shorten time-to-market for their products.

In terms of logistics, AI can optimize supply chain operations by predicting demand fluctuations, optimizing inventory levels, and identifying the most efficient routes for transportation. AI algorithms can analyze historical data, market trends, and external factors to forecast demand accurately. This enables manufacturers to adjust production schedules, manage inventory levels, and ensure timely delivery of products to customers, ultimately improving customer satisfaction and loyalty.

Lastly, AI-powered chatbots and virtual assistants will revolutionize customer service in the manufacturing industry. These intelligent systems can provide instant support, answer customer inquiries, and guide them through troubleshooting processes. By leveraging natural language processing and machine learning, AI chatbots can understand and respond to customer queries in a human-like manner, enhancing the overall customer experience and reducing the need for human intervention.

Final Thoughts

The future of AI in manufacturing is promising. With emerging trends such as AR, VR, data analysis, predictive analytics, demand forecasting and collaborative robots, AI will revolutionize the industry by improving productivity, product quality, and customer satisfaction. Manufacturers who embrace AI technologies will be well-positioned to thrive in the increasingly competitive global market.

Contact us to learn more about how AI can transform your manufacturing operations. We look forward to hearing from you!

Frequently Asked Questions

Can AI completely replace human workers in the manufacturing industry?

While AI has the potential to automate certain tasks and improve efficiency, it is unlikely to completely replace human workers. The human element remains essential for critical thinking, problem-solving, and decision-making.

Manufacturing is a complex industry that requires a combination of technical expertise, creativity, and adaptability. While AI can excel at repetitive and mundane tasks, it still lacks the ability to fully replicate the nuanced skills and judgment that humans possess. Human workers bring a unique set of qualities to the table, such as emotional intelligence, intuition, and the ability to navigate complex situations.

Furthermore, the integration of AI into manufacturing processes often involves a collaborative approach, where humans and machines work together to achieve optimal results. This symbiotic relationship allows AI to augment human capabilities, leading to increased productivity and innovation.

How can manufacturers ensure the ethical use of AI in their operations?

Manufacturers should establish clear ethical guidelines and ensure transparency in the use of AI. Regular audits and assessments can help identify any biases or unintended consequences that may arise from AI algorithms.

As AI becomes more prevalent in the manufacturing industry, ethical considerations become increasingly important. It is crucial for manufacturers to prioritize the responsible and ethical use of AI to avoid potential negative impacts on society, employees, and the environment.

One key aspect of ensuring ethical AI use is the establishment of clear guidelines and principles that govern the development and deployment of AI systems. These guidelines should address issues such as data privacy, algorithmic transparency, and accountability. By setting these standards, manufacturers can ensure that AI is used in a fair and responsible manner.

Regular audits and assessments of AI systems can also help identify any biases or unintended consequences that may arise. These evaluations should involve diverse stakeholders, including ethicists, data scientists, and representatives from affected communities. By conducting thorough assessments, manufacturers can mitigate potential risks and ensure that AI systems are aligned with ethical standards.

What are some other industries benefiting from AI?

AI is being utilized across various industries (e.g. healthcare, finance, retail) In each of these sectors, AI is transforming processes, optimizing operations, and improving customer experiences.

In the healthcare industry, AI is revolutionizing diagnostics, drug discovery, and patient care. AI-powered systems can analyze medical images, detect diseases at an early stage, and assist in personalized treatment plans.

In finance AI algorithms can analyze vast amounts of financial data in real time, enabling more accurate risk assessments, fraud detection, and personalized financial advice.

Retailers are leveraging AI to enhance customer experiences and optimize supply chain management. AI-powered chatbots provide personalized customer support, while recommendation systems offer tailored product suggestions.

These are just a few examples of how AI is revolutionizing various industries. The potential of AI is vast, and its impact will continue to expand as technology advances and new applications are discovered.